Exploring the Manufacturing Process of Custom Membrane Switches

Exploring the Manufacturing Process of Custom Membrane Switches

Blog Article

Why Membrane Layer Switches Over Are Crucial for Durable Control Equipment

Membrane layer switches play a crucial role in making sure the toughness and reliability of control systems across various markets. As we explore the multifaceted benefits of membrane layer buttons, it comes to be evident that their value goes beyond plain performance, affecting individual experience and operational effectiveness.

Overview of Membrane Layer Switches

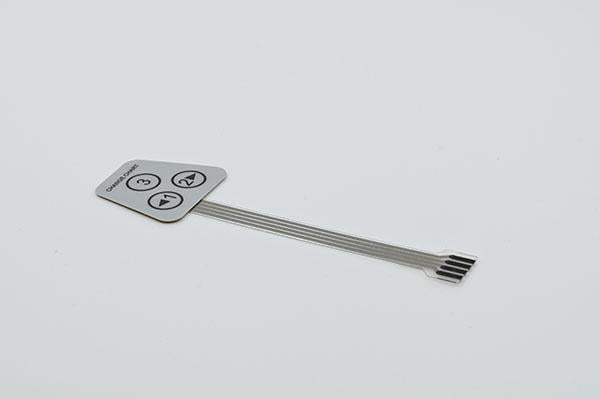

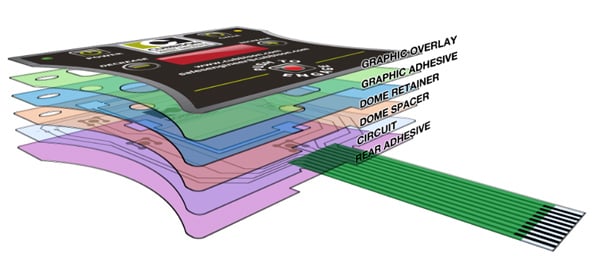

Membrane buttons are versatile and reliable parts generally used in numerous digital control systems. These buttons contain numerous layers, including a visuals overlay, a spacer layer, and a printed circuit layer. The graphic overlay supplies both useful and aesthetic design, while the spacer layer makes sure that the switches are turned on just when pressed. The printed circuit layer consists of conductive traces that complete an electrical circuit when the membrane layer is pressed, allowing the device to react to customer inputs.

Membrane buttons are usually preferred in applications calling for a compact and lightweight layout, making them suitable for handheld tools, medical equipment, and commercial machinery. They can be personalized to fulfill details customer demands and can include different functions such as backlighting, tactile responses, and several shades. Membrane layer buttons are resistant to dust, dampness, and impurities, making them suitable for settings where longevity is vital.

Benefits of Durability

In numerous applications, the longevity of membrane changes deals substantial advantages that enhance their overall efficiency and integrity. These buttons are developed to withstand extreme atmospheres, making them suitable for use sought after conditions such as high humidity, severe temperatures, and exposure to chemicals. Their robust building and construction aids to stop damages from physical effect, making certain durable performance and minimizing the demand for regular substitutes.

Additionally, membrane layer buttons are resistant to damage, which is important in applications where regular communication occurs. This durability equates to lower maintenance prices, as companies gain from minimized downtime and fewer service disturbances. The encapsulated style of membrane changes protects inner elements from dirt and dampness access, additional contributing to their life-span (membrane switch).

Another advantage is their ability to maintain regular performance gradually. With a high resistance for mechanical stress and anxiety, these switches protect their tactile responses and electric honesty, making certain user contentment. Inevitably, the longevity of membrane changes not just boosts functional efficiency yet likewise promotes confidence in their dependability, making them a recommended selection for control systems throughout different markets.

Applications in Different Industries

Resilient control systems using membrane switches discover considerable applications across an array of industries, each taking advantage of the distinct attributes these buttons use. In the clinical sector, membrane switches are crucial for devices such as client displays and analysis devices, where other dependability and ease of cleansing are vital. Their resistance to dampness and contaminants ensures they keep performance in sterile atmospheres.

The vehicle industry leverages membrane buttons for dashboard controls and infotainment systems, where they provide sleek, low-profile user interfaces that enhance user experience. These buttons are additionally created to stand up to severe conditions, consisting of exposure to severe temperature levels and vibrations.

In commercial settings, membrane layer buttons are frequently used in machinery control panels, offering responsive feedback and sturdiness necessary for high-usage applications. Their capability to withstand chemicals makes them suitable for making environments where spills and pollutants are constant.

Consumer electronic devices, such as kitchen appliances and push-button controls, also utilize membrane buttons for their convenience and cost-effectiveness. On the whole, the versatility and robust nature of membrane layer switches over make them essential throughout various industries, making certain effective procedure and durability in control systems.

Style and Aesthetic Appeal

While functionality is critical, the layout and aesthetic appeal of control systems furnished with membrane layer switches play a critical role in individual interaction and overall experience (membrane switch). The aesthetic style of these buttons can dramatically affect customer understanding and interaction. A well-designed membrane layer switch improves the appearance of the tool, making it a lot more appealing to customers and promoting a connection between the individual and the item

Membrane changes use a large amount of versatility in design, permitting suppliers to customize graphics, colors, and appearances to line up with brand identification and item looks. Making use of vivid shades and distinctive patterns can attract focus, while tactile responses can strengthen the individual's interaction with the device. Additionally, the capability to incorporate LED signs and backlighting right Full Report into the membrane layer switch style provides both useful and visual advantages, enhancing visibility and usability in various environments.

Enhancing Individual Experience

Moreover, membrane switches can be customized to include graphical user interfaces, improving usability by offering info in a clear and instinctive way (membrane switch). This modification can consist of icons, labels, and color coding that guide customers through complex performances effortlessly. Additionally, their flexibility enables combination in various settings, making sure consistent performance whether in industrial machinery or consumer electronics

The resilience of membrane switches additionally plays a vital duty in individual experience. By withstanding severe conditions and prolonged usage, these switches minimize the possibility of system failings, thus promoting integrity and individual confidence. Inevitably, the critical use membrane layer switches over not only raises functionality yet likewise considerably improves customer interaction with control systems, making them an essential component in contemporary style.

Conclusion

Report this page